The construction industry is probably one of the oldest industries in the world and still growing as more advanced equipment are being designed today. Since, the construction industry uses heavy equipment like dumpers, excavators, cranes, Ready-Mix-Concrete (RMC) trucks, tippers, etc.; research firm MarketsandMarkets, estimates that the heavy equipment market will reach $166 billion by 2020.

The construction industry is probably one of the oldest industries in the world and still growing as more advanced equipment are being designed today. Since, the construction industry uses heavy equipment like dumpers, excavators, cranes, Ready-Mix-Concrete (RMC) trucks, tippers, etc.; research firm MarketsandMarkets, estimates that the heavy equipment market will reach $166 billion by 2020.

Needless to say, this is a huge market that directly affects the profits and efficiency of the construction industry. Remote monitoring and analytics together will help to increase the productivity of the heavy equipment fleets. An increase in productivity will directly relate to increase in profits.

Common challenges in construction industry

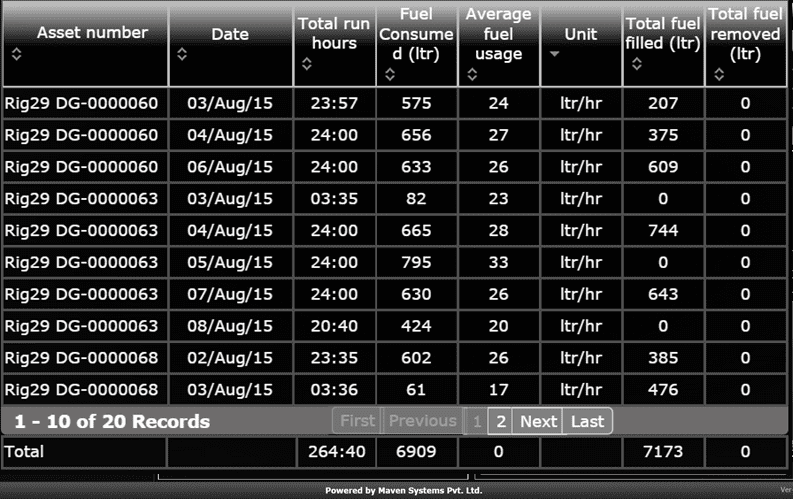

Fuel theft

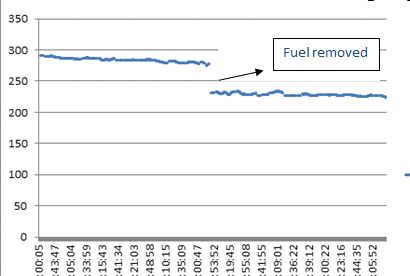

While there are no official numbers, fuel thefts eat up between 5 to 25% profits and ends up increasing the operational costs of construction. Fuel theft occurs when either the expected amount of fuel is not filled or by siphoning off fuel after it has been filled.

Equipment abuse

Equipment abuse translates to using equipment in a way that causes damage to the machine. The reasons for equipment abuse could include operator inefficiency, lack of training and lack of pre-emptive maintenance, etc.

Unauthorized trips / work

The staff hired for operating the heavy equipment may use it for unauthorized work such as using the heavy equipment on different sites. This is especially prevalent in India, where multiple construction sites are placed nearby and different firms operate in them.

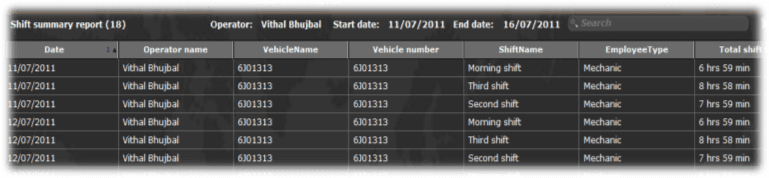

Unregulated work hours

Usually site supervisors have schedules for smooth running of the sites. However, equipment operators do not follow the outlined schedules which results in unnecessary delays and consequently increases the operational cost.

The Solution: Analytics

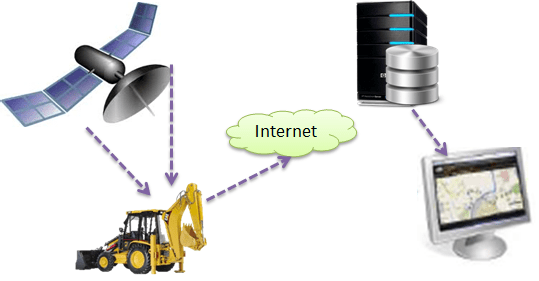

Analytics of the data collected from heavy equipment will help in eliminating delays and keeping the operational costs in check. The solution will use a GPRS based device to upload all the vital data about the equipment to the Internet. This will enable remote monitoring and help the fleet owners get a clear picture of all of the equipment being used at the same time.

Fig. 1: Architecture of the solution

Fig. 1: Architecture of the solution

The data to be monitored and its advantages include:

Fuel

Fuel is one of the biggest operational leaks in the construction industry. A clear picture of how much fuel is filled and how much has been used will help in understanding where thefts have occurred and when the machine needs maintenance.

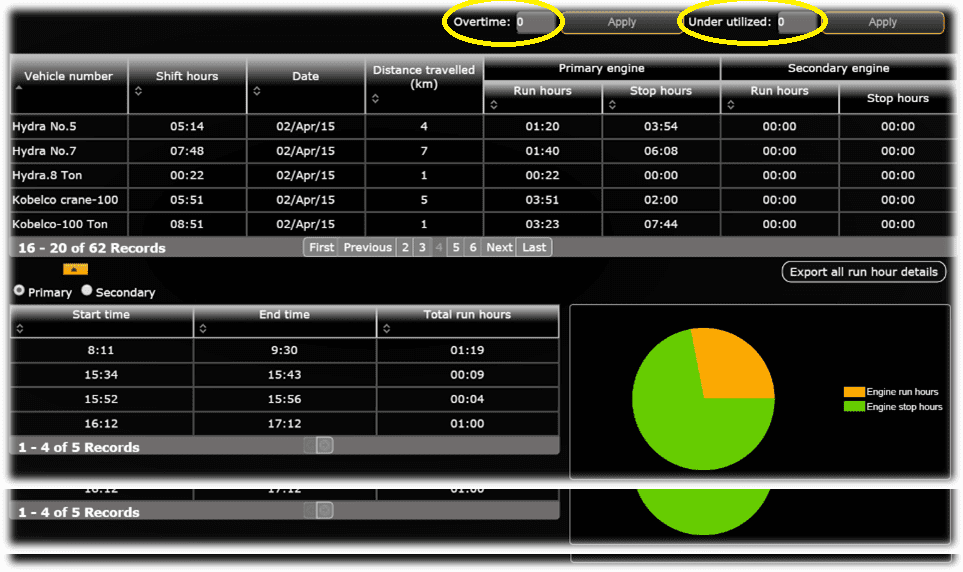

Operational hours

The operational hours of the equipment help in understanding the usage pattern and trends, which can further determine, when the equipment needs maintenance or if it’s overworked. This benefits in increasing both, the life and productivity of the equipment.

Fig. 4: Operational efficiency

Fig. 4: Operational efficiency

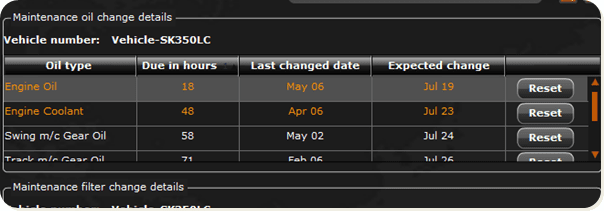

Fig. 5: Oil change reminders using analytics

Fig. 5: Oil change reminders using analytics

Location and speed

Location and speed is important for trucks and dumpers. The idea here is to avoid unauthorized trips, and over-speeding of vehicles, that can cause harm to people.

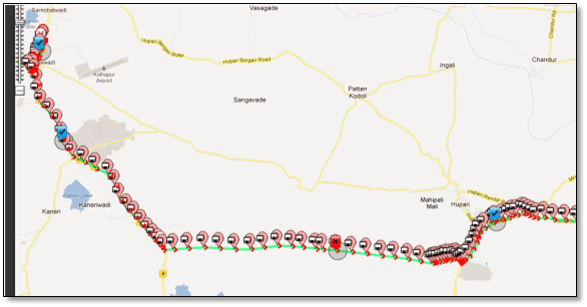

Fig 6: Real time location of the equipment

Fig 6: Real time location of the equipment

Operator efficiency

Operator usage is a huge factor in both equipment health and the overall productivity of the site. Thus, it’s important to know the work times of the operators and how the equipment was used by them.

Conclusion

The concluding statement for the construction industry is that, the sooner they opt for remote monitoring and analytics, faster they will realize its benefits. While they have managed fine before this, it is undeniable that remote monitoring gives them a superior insight about their sites and analytics will help them to make more informed decisions. Remote monitoring is the future of construction equipment market.