Power transformers are an integral part of any power distribution network. Owing to humongous capital and maintenance cost involved for this equipment, there exists a huge scope to optimize expenses thereby improving the revenue.

Where is the struggle for distribution companies?

- Unavailability of dashboards or tools to visualize the status of multiple parameters associated with power transformer

- Unforeseen failures in transformers leading to downtime and penalty

- Loss of asset life due to continuous faults/failures

- Poor maintenance planning

- Unavailability of advanced solutions to monitor the health of transformers

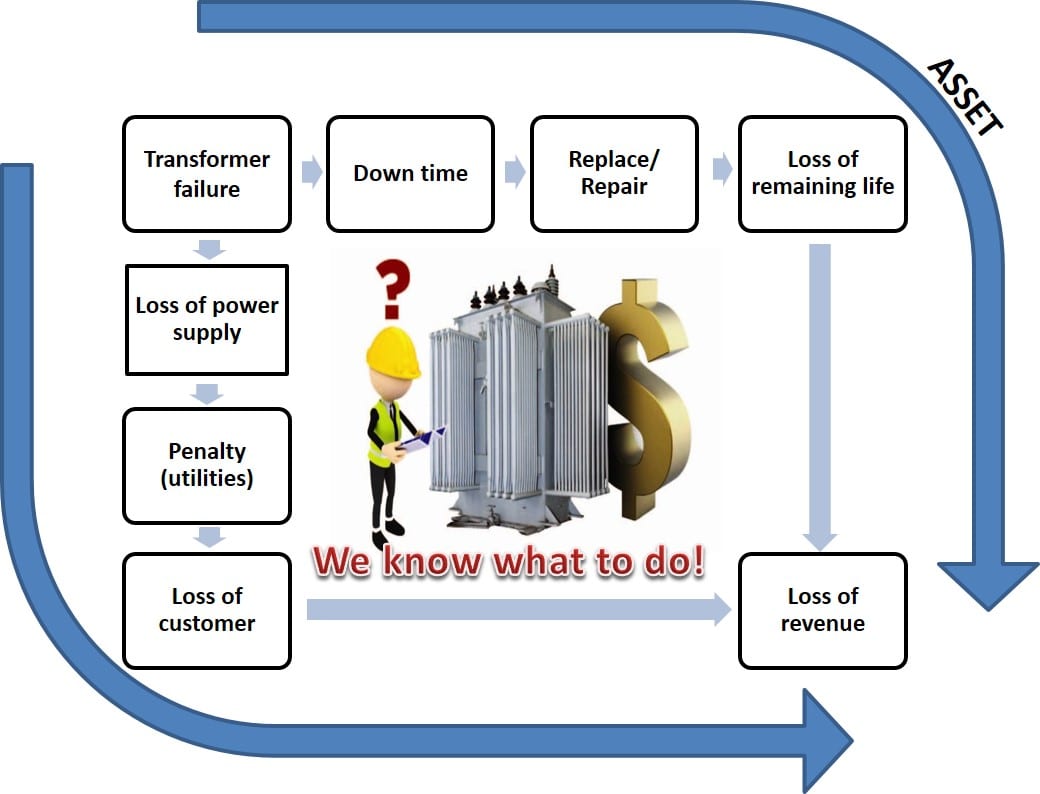

What happens when transformer fails?

Transformer failure can lead to serious loss of revenue in multiple ways. When transformer fails, it leads to isolation of its customer from the grid, and the distribution companies are bound to pay penalty. This adds to the loss of revenue on account of its failure in supplying the generated power to its customer.

| Consequences of a failure |

The other important loss is the power transformer itself. Due to improper maintenance or utilization, there is loss of operational life of transformer. Every fault reduces the transformer’s remaining life in addition to the cost incurred towards repairing/ replacement. This leads to loss of revenue for the distribution company operating the transformer

How is the solution developed?

The proposed model dwarfs the limitations with respect to the operator’s capability, limited input data, absence of intelligent monitoring devices and inability to correlate multiple test results.

The proposed model dwarfs the limitations with respect to the operator’s capability, limited input data, absence of intelligent monitoring devices and inability to correlate multiple test results.

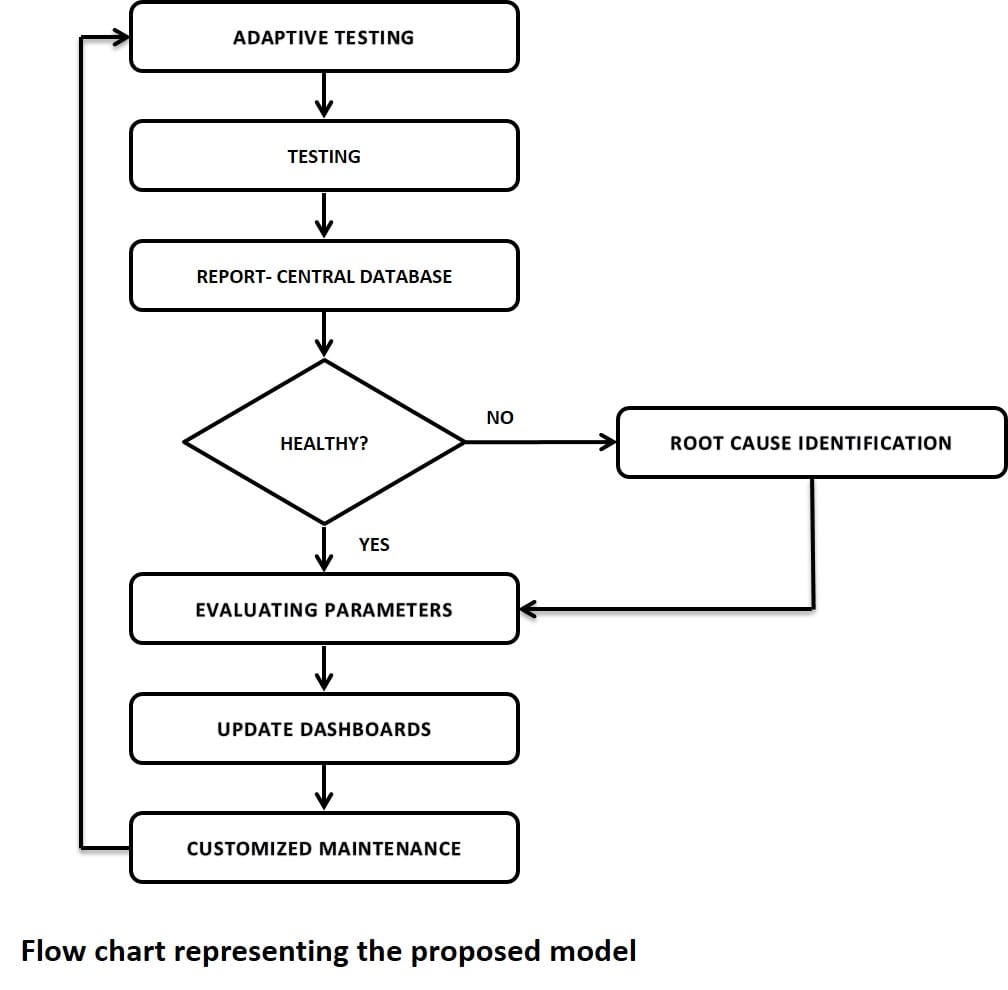

The model is based on developing an adaptive testing/maintenance plan based on the transformer’s history and domain expertise instead of adhering to a static testing plan. By this way, the distribution company can optimize maintenance cost and avoid potential failures.

Multiple tests are conducted as per the adaptive testing plan and the results are updated to a central database from which the model fetches data for analysis. The reports are analyzed simultaneously, and various calculated parameters are evaluated for determining health index of transformer. In case of potential faults or failures, the type of fault is identified before evaluating the calculated parameters.

Dashboards are the most important part of this model which visualizes trending of various test parameters and calculated parameters, and customize the quantity of data to be displayed as per our requirement. Based on the analysis, the model updates the adaptive testing plan and the next test date is determined. Following parameters/tests are considered for this model building:

- Dissolved Gas Analysis (DGA)

- Oil Sample Test (OST)

- Loading History

- Winding hot spot & Top oil Temperature

- Degree of polymerization or Furanic compound analysis

Bringing Analytics to Analysis:

The key to this approach is to maximize the amount of information that can be utilized from existing data set. The history of transformer forms the base on which the model is developed. Accuracy of the model is improved with increased availability of data, which has enough data points (failure points) for tuning the model, and that data is fed into the model. Various faults are also identified based on the developed relationships and reference standards (IEC/IS)

What does a solution dashboard look like?

Dashboards created for transformer health monitoring and assessment are shown below. Box plot enables us to understand and analyze the overall distribution of recorded values. Trending of multiple parameters helps the operator in monitoring the variation of each parameter with reference to its limits over a period of time, and plan necessary corrective actions or maintenance activity in case of abnormal variations. Fault identification using IEC gas ratios is another critical feature of this model. To assess the overall condition, a numerical value is computed to represent the health of transformer and the same is compared along with its age. A unique solution for monitoring various parameters individually and to assess overall health of the transformer is thus achieved with this model.

How will solution help Power distribution companies?

The solution helps the distribution companies in the following areas,

- Monitor asset condition

- Fault prediction

- Increase reliability

- Asset life extension

- Schedule maintenance activity

- Downtime management